Speed of Air (SoA) Engine Technologies has developed patented technology to enhance the efficiency of medium-duty Cummins, Powerstroke and Duramax engines, providing measurable performance and fiscal benefits.

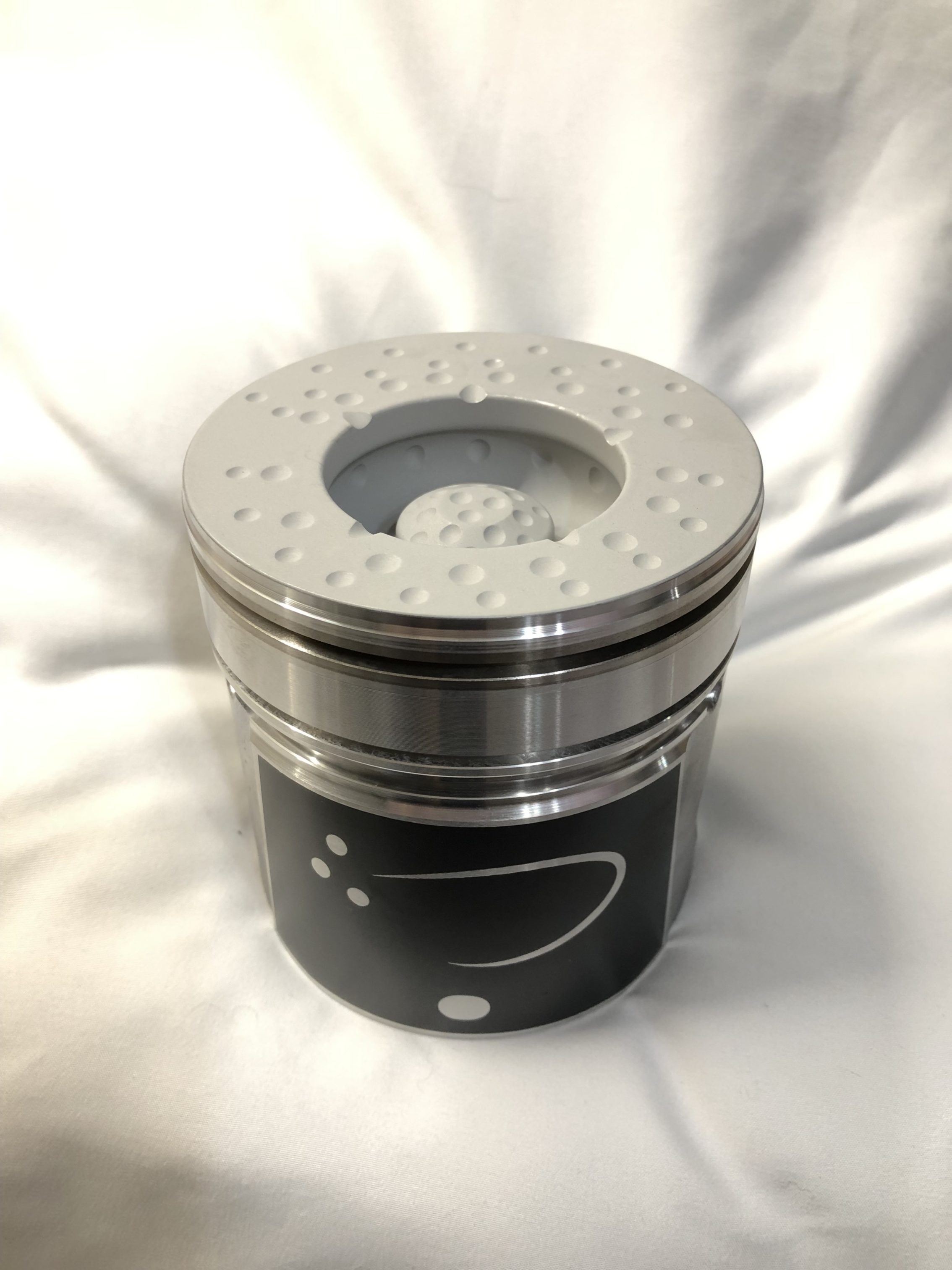

SoA’s patented piston treatment on its Hyperformance Pistons provides increased torque, horsepower, reduced emissions and greatly improved fuel efficiency. These improvements also contribute significantly to extending engine life and reducing service intervals.

The fuel savings alone, documented by independent commercial users, are as much as 25 percent and more, a critical aspect for fleets facing higher fuel prices.

The SoA patented technology primarily consists of precise, CNC-machined indentations on the piston top, called turbulators, but most often described simply as “dimples.”

This precisely designed and manufactured technology is executed to exacting tolerances under ISO 9001 quality standards.

These turbulators create a thinner, well-attached boundary layer between the air-fuel mixture, its flame front and the combustion chamber walls. This thin, turbulent layer allows the combustion flame front to burn much closer to the cool metal walls of the combustion chamber, thereby increasing overall combustion efficiency.

The result is significant reductions in fuel consumption, reduced emissions, increased torque and horsepower, improved drivability and pulling power.

Lower soot emissions translates to better engine longevity and fewer service intervals.

SOA’s Hyperformance pistons also include the application of aerospace-proven thermal barrier and anti-friction coatings on the piston crowns and skirts, respectively.

The thermal barrier coating retains heat in the combustion process, thus providing additional efficiency and power. The anti-friction coating minimizes abrasion and resistance for even more efficiency.

The combined technologies of a Speed of Air Hyperformance piston provide documented and significant benefits with a distinct value proposition.

Lab tests as well as years of real-world operational field testing in a wide variety of applications confirm the results.

Notably, DFC Diesel, an innovative industry leader and Canada’s largest diesel engine remanufacturer, has been independently testing SoA technology for nearly two years in more than a dozen Dodge, Ford and Chevy trucks. DFC’s testing has been so successful that this company is now offering an entire line of Speed of Air remanufactured engines.

During testing, DFC Diesel observed fuel consumption reductions of 25% or more with factory tuning, an average of 5% increases in torque and horsepower, NOx reductions as high as 80%, and the ability to extend oil change intervals by 50% due to decreased soot and fuel dilution.

Observed benefits also include reduced regeneration cycles, DEF consumption, and visible exhaust/opacity, along with noticeably smoother and quieter operation.

To manufacture these custom piston kits, SoA has licensed United Engine and Machine Co. (UEM), a leading manufacturer of pistons with over 100 years of experience and a well-earned reputation for quality. As a family-owned and operated company, UEM has in-house design, development and manufacturing capabilities that allow this firm to meet nearly every type of engine’s piston needs.

Speed of Air Engine Technologies is a Reno, Nevada based company dedicated to engineering innovative solutions for the internal combustion engine industry.

SoA’s clean engine technologies promise a clear advantage to industry’s bottom line today, while ensuring a cleaner environment tomorrow.

Looking ahead to the future, SoA has plans for rapid expansion of its piston technology to a number of other engine and fuel applications, including heavy-duty over-the-road and large-bore industrial applications.

For more information, visit www.soapistons.com

0 Comments