(SPONSORED CONTENT)

It’s time to remind your shop customers to stop replacing just the belt! Not only are they missing out on a business opportunity, but a systems approach to front-end accessory drive (FEAD) system maintenance is the best bet against comebacks. Replacing all components, along with the belt, increases uptime and enhances vehicle performance. That’s because the belt and components in a drive system wear out in concert, making a complete system replacement the most ideal repair solution.

Dayco makes it simple to get all the parts for a front-end system repair with a comprehensive line of kits – so it’s easier for you to stock and offer everything that’s needed in ONE part number when it’s time for installation. Kits ultimately:

- Prevent slip and misalignment issues

- Minimize comebacks

- Save 10-15% vs. buying the parts independently

- Can increase both shop and jobber revenue significantly

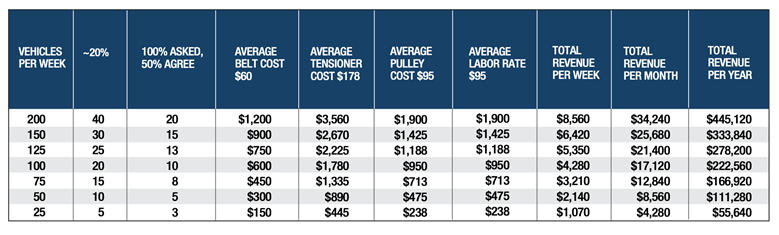

Make sure your customers are aware of this untapped market opportunity. If just 20% of the vehicles that need a belt replacement also have a new tensioner and pulley installed for best performance, the revenue increase will add up week over week.

Dayco’s Top 5 Tips for FEAD System Inspection

#1 – Recommend Shops Check the System around 96,000 Kilometers

Most OEMs recommend serpentine belt inspections around 96,000 kilometers and service around 128,000 kilometers. They should be listening for noises and looking for any signs of wear.

#2 Take Advantage of Dayco’s Free Belt Wear Gauges

Did you know that Dayco’s aWEARness gauges are free? Just place an order and send these useful tools to your garage customers so that they can correctly inspect a belt. Today’s belts wear differently than their predecessors, so this tool helps measure rib depth and rib profile, making it easier to identify if the belt is worn.

#3 – Suggest a Kit Instead of Just a Belt When it’s Time for Replacement

You may get a call for just a serpentine belt or a timing belt from a local shop, but this is a great time to remind customers that they can Improve performance, reduce comebacks and help motorists save money by using a kit like the Dayco serpentine belt kit or Dayco timing belt kit. These kits include all the parts needed to ensure the repair job is done correctly the first time.

Dayco offers a full line of OE-quality drive system kits for today’s vehicles with coverage for millions of applications. Each kit includes all the application-specific parts needed to do the repair right the first time.

Dayco Serpentine Belt Kits feature a premium tensioner with flat spring technology, a durable pulley with permanently lubricated bearings and a long lasting Dayco serpentine belt.

- Handles higher workloads and temperatures

- Reduces vibration and increases belt life

Dayco Timing Belt Kits include tough wear-resistant belts, idler pulleys with tighter dimensional tolerances and tensioners that resist cracking and fatigue.

- Reduces the possibility of comebacks

- Available with and without water pumps

Dayco Timing Chain Kits include top-grade timing chains that prevent stretch, precision-machined crank sprockets and cam sprockets for a flawless fit as well as tensioners, high-grade plastic guides, seals, VVT solenoids and cam phasers if the application calls for it.

- Backed by an industry-best two-year or 60,000 mile parts and labour warranty

- Easy to follow instructions and extensive library of training videos

Tap into Our How-To Videos

For helpful tips and rich content from the Dayco tech team, visit the Dayco Tech Hub’s extensive video library.

1. Measuring Belt Wear

2. Serpentine Belt Maintenance Tips

3. Top 2 Causes of Timing Chain Repair

4. Timing Belt Installation and Repair Tips

0 Comments