JOBBER NATION DIGITAL FEATURE

Today’s chassis parts market is driven by the need to meet the quality and service levels of customers, while also keeping pricing in line with their expectations.

In the face of continual parts proliferation, and growing competition, this is no easy task for the parts wholesaler.

Knowledge is your best weapon against sub-standard products on the market.

Seek supply partners that:

-

Provide high-quality “better than OE” parts.

-

Aftermarket offerings that improve over OE designs in performance and installation will bolster your market performance. A prime example is the MOOG Problem Solver link kits that feature moulded bushings that centre washers and a barrel lock nut that can be threaded on even if the bolt is flush with the washer. Credit: MOOG Steering & Suspension/Federal-Mogul Motorparts.

Provide coverage for YOUR customer base.

-

Provide customer seminars to show the real benefits of quality parts.

-

Provide counter and outside sales personnel training.

-

Have digital assets such as You Tube videos, web training, online help.

-

Have strong warranty programs.

-

Have effective sell sheets offering product and coverage information.

To be effective, jobbers should ensure:

-

Salespeople have something to talk about when they go on calls.

-

Counterpeople are knowledgeable about supplier offerings.

-

Pricing allows the repair facility to earn an acceptable (or better!) profit.

-

Counter and outside sales staff regularly talk about strong warranty and low warranty rates.

-

Outside sales staff always bring a featured part with them on sales calls.

Multi-link rising in popularity, bringing new challenges

According to industry suppliers, sway bar links are becoming among the most popular categories, alongside the popular control arm, due to the proliferation of multi-link suspensions.

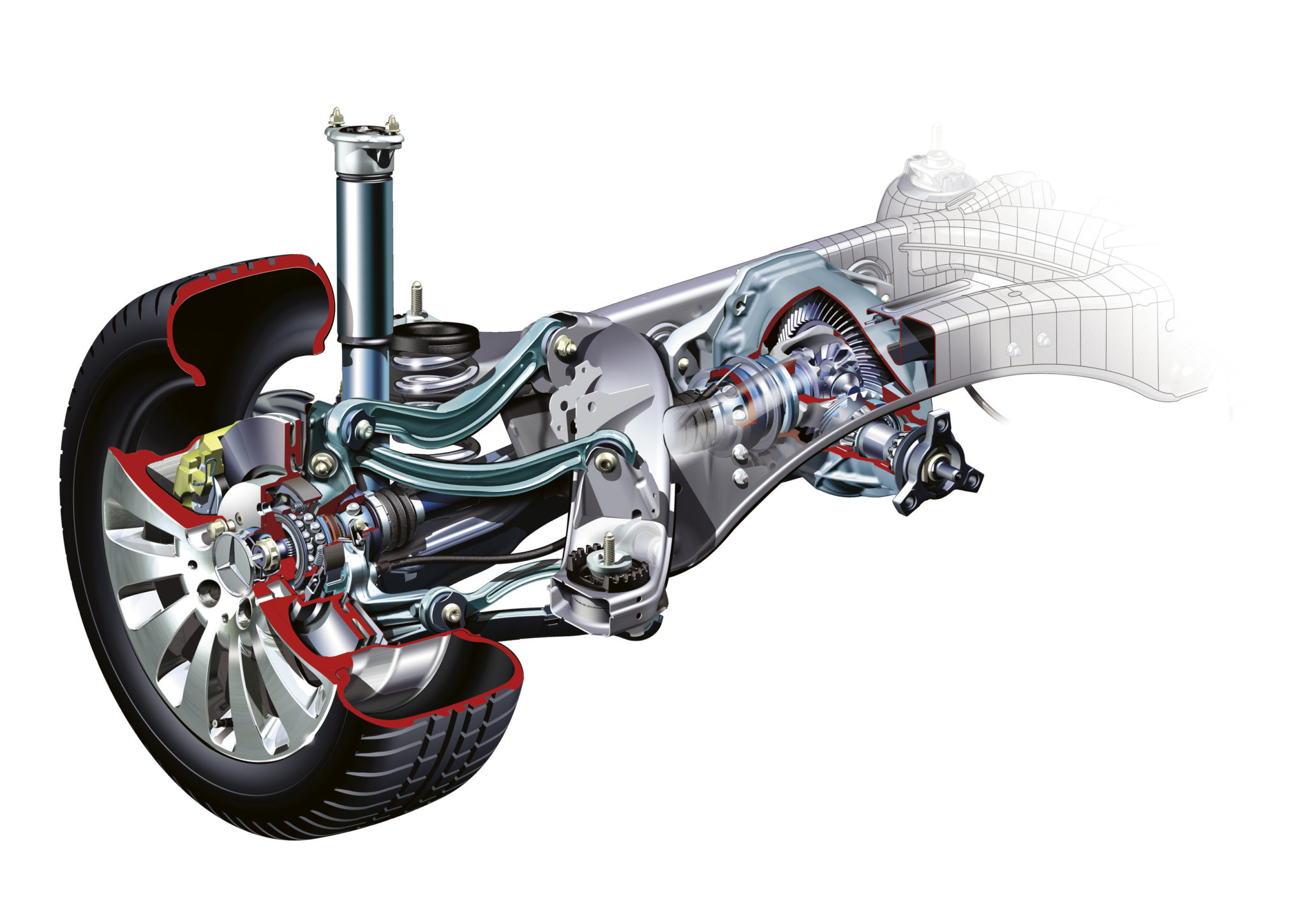

This Mercedes-Benz C-Class cutaway serves as a good example of how complex suspension systems became even as far back as 2007. The designs have since spread across models at virtually all price points.

Some suspension designs can contain as many as 10 suspension links, all of which must work in concert to return the vehicle’s handling performance.

Multi-link suspensions are driving the need for these new parts, but are also presenting challenges for shops as they are more complex to work on. Parts must be dimensionally very accurate to ensure proper post-repair alignment.

In addition, the Advanced Driver Assistance Systems may require reset steps at the alignment stage to ensure their proper, safe, continued operation.

Failure to properly execute this post-repair reset step could lead to ADAS malfunctions and error codes. Failure to do so could also lead to stiff steering and other symptoms that could be improperly blamed on the chassis parts used.

Special thanks to John Thody, XRF Chassis Parts, Dany Girard, Transit Warehouse, Federal-Mogul Motorparts, and Hunter Engineering for information used in this article.

0 Comments